The packaging products manufacturer contracted Maxbyte to digitize three factories with the eventual goal of digitizing all 15 manufacturing facilities on its Industry 4.0 transformation journey.

DUBAI – May 10, 2023: Hotpack, the UAE-based global leader in disposable packaging products manufacturing, has signed an agreement with Maxbyte, an industrial digital, robotics, and training solutions provider to digitize all 15 of its factories in the UAE and other countries. With the contract, Maxbyte will work as a strategic partner to help Hotpack achieve Industry 4.0 transformation across its entire operations.

Industry 4.0 refers to the fourth industrial revolution that is characterized by the use of advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and big data analytics to make manufacturing more intelligent, connected, and sustainable. It aims to transform the way organizations design, manufacture, distribute, and service their products to be more optimized.

Hotpack recently performed a demonstration of the plan of transformation for representatives from the Abu Dhabi Department of Economic Development (ADDED) during Industry 4.0 Demo Day at the company’s Abu Dhabi facility. The ADDED officials were impressed by the demonstration and commended Hotpack for its efforts to achieve Industry 4.0 transformation in its facilities, setting the standard for the wider industry in the UAE. The ADDED officials also provided suggestions to improve the process of transformation and implementation of the new technology.

Commenting on the contract, Mr. Abdul Jebbar PB, Group Managing Director of Hotpack Global, said, “We are happy to embark on our transformation journey to achieving the highest Industry 4.0 maturity level and we are looking forward to our partnership with Maxbyte to facilitate that journey. Maxbyte solutions are modular, scalable, fast, secure, affordable and platform agnostic, making them the perfect choice to help us achieve digitization.”

“Industry 4.0 is revolutionizing the way organizations design, manufacture, distribute and service their products and makes the manufacturing connected, smarter and sustainable. Whether it is digital maintenance systems or real-time overall equipment effectiveness, it will enable us to maximize revenue growth, reduce costs and increase asset utilization. Most importantly, we will be able to drive these financial objectives with visibility, transparency, predictability, and autonomous adaptable systems,” he added.

Mr. Anvar PB, Group Technical Director of Hotpack Global, said, “For the first wave of Hotpack’s Industry 4.0 transformation roadmap, the company will begin transforming three of its factories, located in Dubai Investments Park 2, National Industries Park, and Umm Al Quwain. The ultimate goal of the transformation roadmap is to achieve the highest level of Industry 4.0 maturity at the end of the three-to-five-year period. Eventually, Hotpack aims to digitize all 15 of its manufacturing plants, creating a smart, connected, and sustainable enterprise.”

Mr, Ramshankar CS, CEO of Maxbyte, said, “We are happy to work with one of the largest manufacturers in the Middle East. They have an extensive network across multiple countries that will benefit greatly from our deep tech, market-validated products, and solutions in digitization, robotization and decarbonization to improve their operational efficiency. We look forward to helping Hotpack achieve the highest Industry 4.0 maturity level and beyond.”

According to Mr. Jebbar, the Industry 4.0 transformation is projected to reduce operating costs by 5 to 10 per cent, improve overall equipment effectiveness by 5 to 10 per cent and improve productivity by 15 to 20 per cent. Furthermore, Hotpack’s processes are expected to become 100 percent paperless and will enable the company to completely avoid manual data entry.

Hotpack and Maxbyte will begin the transformation process by assessing the current Industry 4.0 transformation maturity level of the manufacturer based on the globally recognized Industry 4.0 Maturity Assessment Framework from Acatech, Germany. The assessment will identify the areas of improvement for Industry 4.0 in the Hotpack manufacturing value chain and arrive at a transformation roadmap for the next three to five years.

-Ends-

About Hotpack Global

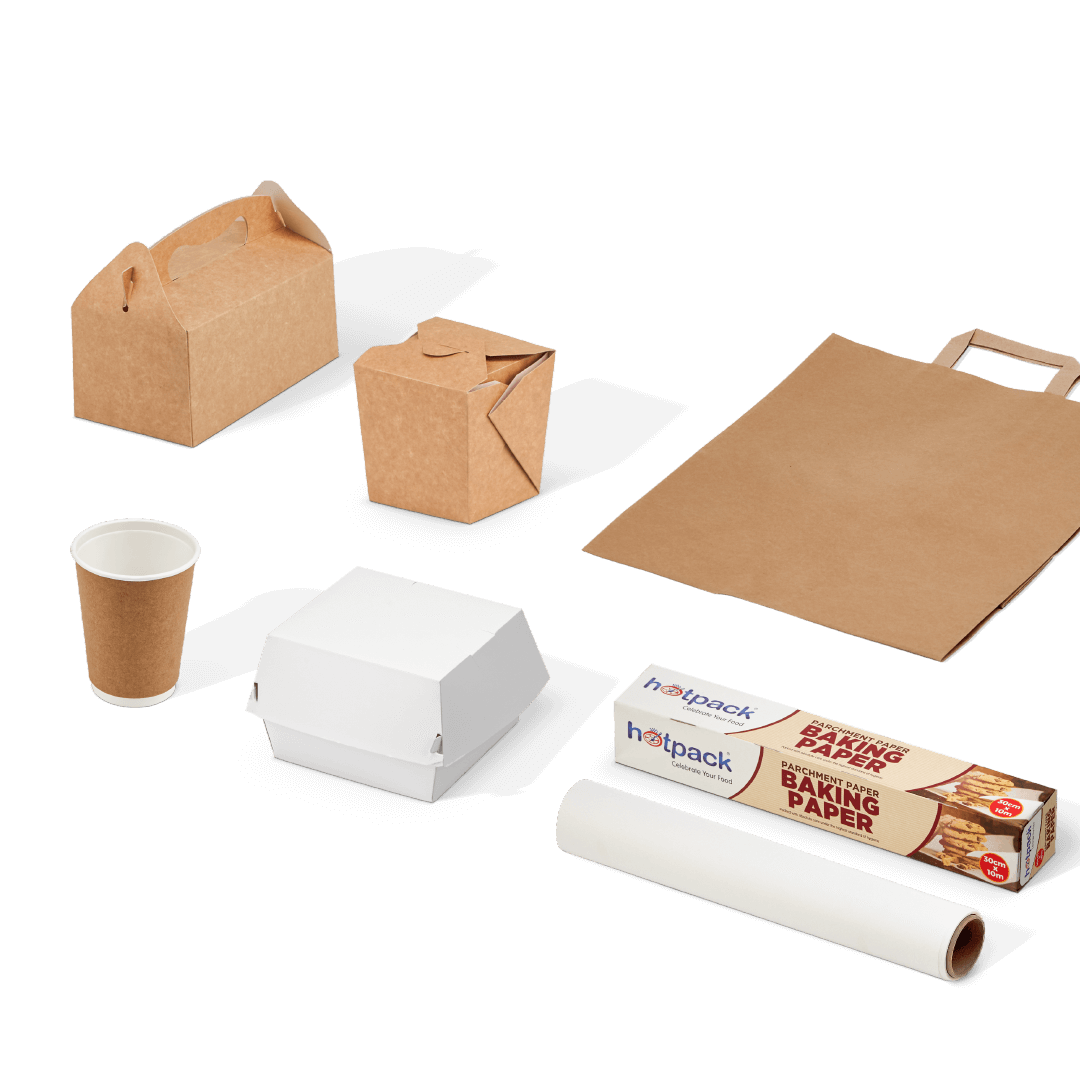

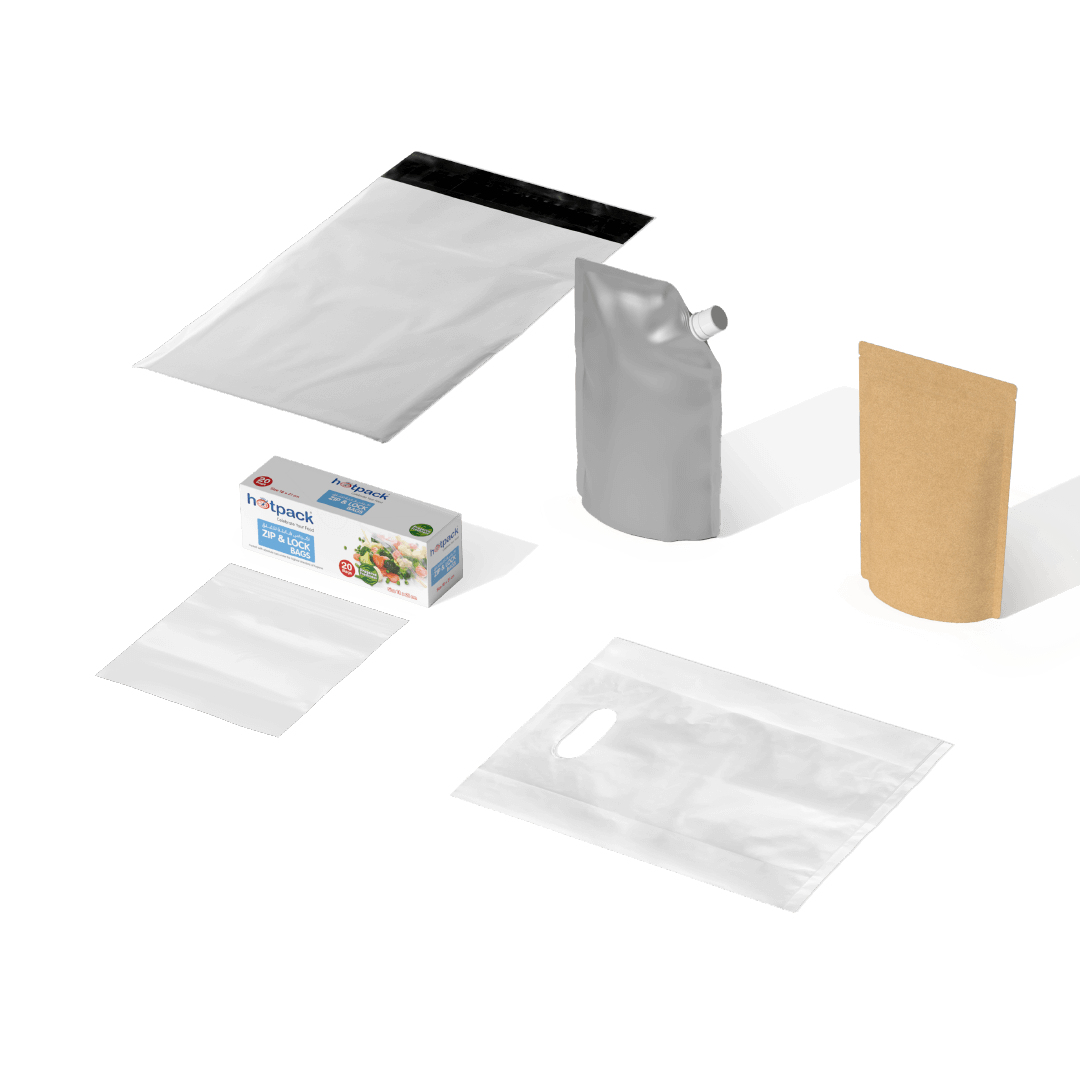

Founded in 1995, Hotpack Global is a recognized leader in both the manufacture and supply of food packaging products. Today, the company has operations in 15 countries which include GCC countries, India, UK, USA, Morocco, Ivory Coast, Nigeria, Spain and Australia. Within a limited span of time, the company has grown to become one of the leading players in the packaging sector because of its reputation for supplying quality products, its reasonable price structure and outstanding service. Hotpack is seen as a one stop shop that offers the complete range of packaging products for HORECA, Retail and Industrial Packaging sectors. It represents other major manufacturing companies worldwide and products are packed hygienically in modern and attractive designs and marketed under “Hotpack” (Disposable Range) and “Soft n Cool” (Tissue Range) brands.

As a food packaging company Hotpack has been certified with BRCGS, FDA, SEDEX, ESMA, PEFC, FSC, ISO 9001: 2015, ISO 22000: 2018, ISO 14001: 2015, ISO 45001: 2018 which ensures the top quality of its products. Hotpack was adjudged winner of the coveted Dubai Quality Award under the category of Dubai Smart Industry Award 2020 for the manufacturing sector. Hotpack today has 47 standalone Retail centres across the MENA offering 600 plus Specialty range products which are not available in Supermarkets. Also www.hotpackwebstore.com is the region’s largest online store for food packaging products. Over the years, Hotpack has become a trusted brand with its excellent products, services and continuous brand communication.

For media queries, please contact

Pradyuth Ramkishore

Watermelon Communications

Dubai, U.A.E.

Email: pradyuth@watermelonme.com