To have control over the quality, Hotpack has made substantial investments in backward integration. With over 25 extruders in different combinations, it has the capacity to produce more than 1000 MT per month of films.

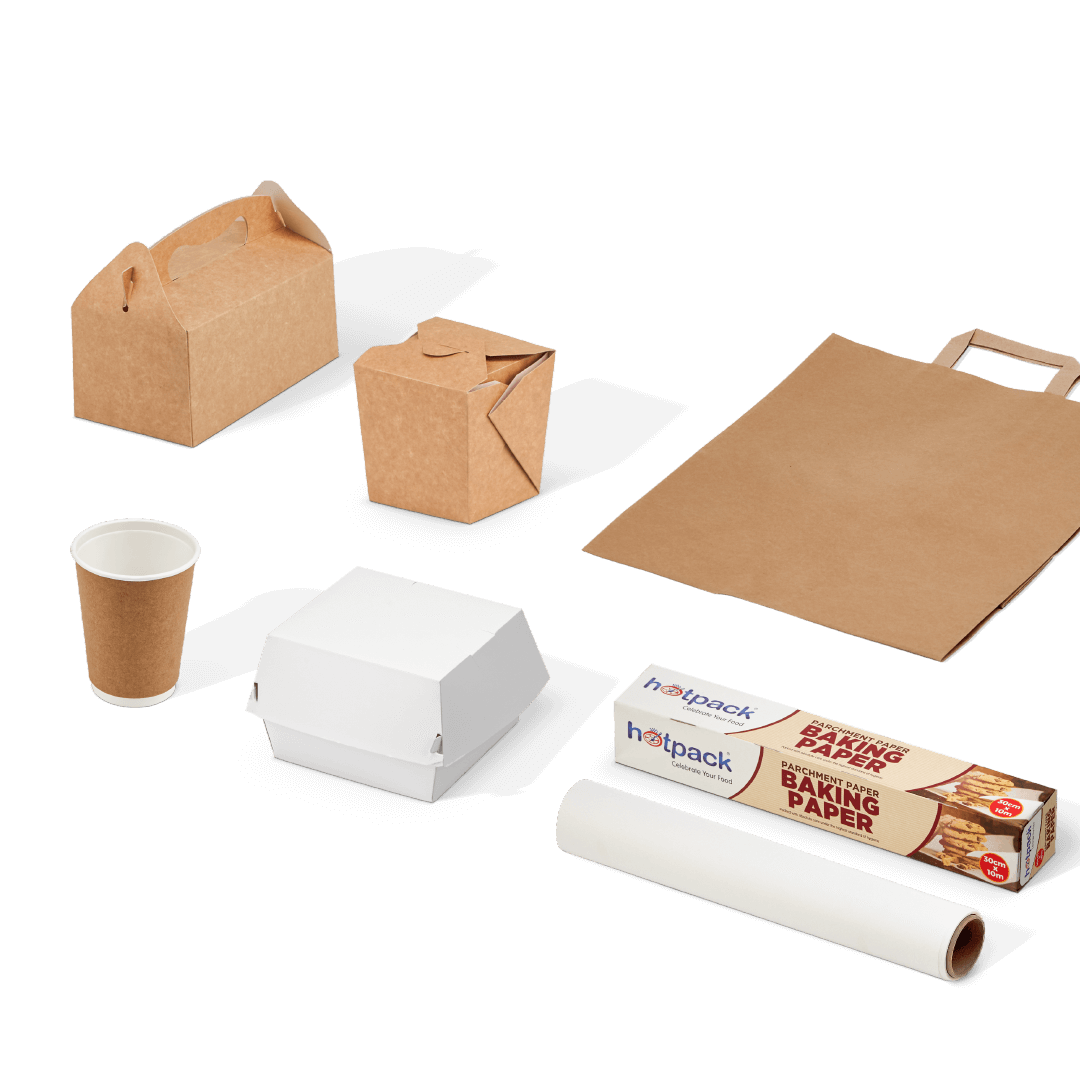

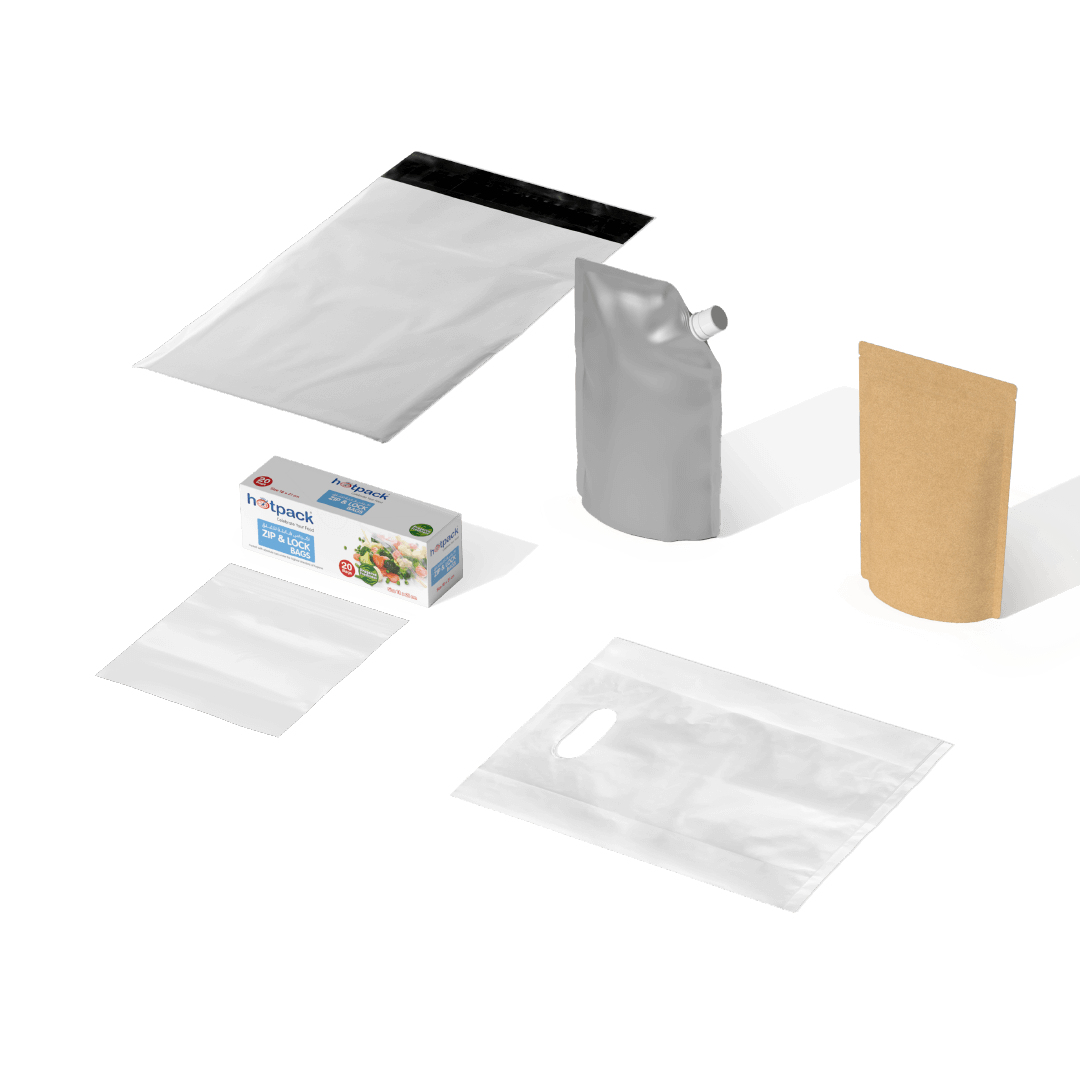

100% of the produced films are recyclable. They are used for various applications like Lamination films, shrink films, T Shirt bags, vegetable bags, zip lock bags, garbage bags, poultry bags, vacuum bags, shopping bags, e commerce bags, courier bags and bakery bags.

With the growing demand for sustainable packaging, this facility is further expanding its capacities and capabilities.

Both the film and the flexible packaging division are supported by multiple printing technologies that could cater to complex demands of the changing consumer behavior.

Hotpack boasts of having Wide web Gravure, Wide Web CI Flexo, Narrow web Flexo. Stack type Flexo, Line Flexo, Digital and Off Set printing process.

In house graphics team has the support of the latest software like Esko graphics to enable high quality reproduction with optimum ink consumption

These plants have all the requisite certifications that include BRCGS and ISO. It is also approved by most Consumer-Packaged Goods companies for supplies of food packaging materials.