-

State-of-the-Art Manufacturing Hub

- Location & Facility Size:

- Our Flexible Packaging Plant in Umm Al Quwain spans 400,000 square feet.

- This facility is designed for large-scale production with the flexibility to adapt to market demands.

- Commitment to Sustainability:

- Nearly 100% of extruded plastic films from this facility are recyclable, reflecting our dedication to global sustainability standards.

- Location & Facility Size:

-

Core Manufacturing Capabilities

- Our Film Division is a cornerstone of our manufacturing operations.

- Installed capacity exceeds 700 MT per month.

- We operate 25 state-of-the-art extruders dedicated to producing high-quality LDPE, HDPE, and PP films for diverse industry needs.

-

Advanced Production Capabilities

- Extrusion Technology:

- Equipped with a wide range of extruders producing diverse plastic films, including LDPE, HDPE, and PP.

- Films are tailored to specific industry needs with various thicknesses, widths, and technical specifications.

- Gravure & Flexo Printing:

- Features state-of-the-art Gravure and Flexo printing technologies.

- Enables high-resolution, multicolor printing with exceptional accuracy, perfect for intricate designs and detailed branding.

- Post-Printing & Lamination:

- Sophisticated lamination machinery enhances barrier properties, durability, and product protection.

- Adheres to the highest standards of food safety.

- Precision Slitting & Pouch Formation:

- Advanced slitting technology offers customized packaging solutions.

- Expertise in preformed pouches, creating various shapes and sizes tailored to industry-specific requirements.

- LDPE Films:

- We produce LDPE films in mono, twin, and triple layers, tailored to specific end-application requirements.

- Technology Integration:

- Each extruder is equipped with advanced technology, including corona treatment capabilities.

- Corona treatment enhances surface energy, ensuring superior adhesion properties essential for various downstream applications.

- Extrusion Technology:

-

Comprehensive Product Offerings

- Application-Specific Packaging Solutions:

- Food & Beverage:

- Provides tailored packaging for snack foods, confectionery, ice cream, pasta, instant fruit drinks, milk powder, tomato paste, ketchup, and mayonnaise.

- Packaging is designed to preserve freshness and extend shelf life.

- Consumer Goods:

- Specialized packaging solutions for tea, coffee, spices, pet food, soaps, detergents, and personal care products.

- Ensures product protection and ease of use.

- Food & Beverage:

- Customization & Flexibility:

- Our technical team collaborates closely with clients to develop customized packaging solutions.

- Offers specialized films with high barrier properties, UV protection, and heat resistance.

- Our Film Division is recognized for its extensive scope, quality, and variety.

- We manufacture and supply extruded films as intermediate products to leading packaging companies.

- These films are vital components in the production of multi-layer laminates, which are combined with other substrates such as PET, BOPP, CPP, and Nylon to achieve desired performance characteristics.

- Application-Specific Packaging Solutions:

-

Innovation & Sustainability Initiatives

- Transition to Recyclable Materials:

- Leading the shift from non-recyclable to recyclable materials.

- Packaging solutions meet sustainability goals and market demands.

- PIR & PCR Material Integration:

- Actively develops and utilizes Post-Industrial Recycled (PIR) and Post-Consumer Recycled (PCR) materials.

- Contributes to the circular economy and reduces environmental impact.

- Future-Ready Packaging:

- Continuous investment in R&D ensures packaging solutions meet current and future sustainability and efficiency requirements.

- Transition to Recyclable Materials:

-

Specialized Films for High-Performance Applications

- Shrink & Laminate-Grade Films:

- We specialize in producing three-layer shrink and laminate-grade films.

- These films are engineered to exhibit controlled shrinkage, enhanced adhesion, and optimal sealing, meeting the rigorous demands of specific packaging processes.

- Application Effectiveness:

- Our films are designed to ensure effectiveness in group packaging and lamination applications.

- Shrink & Laminate-Grade Films:

-

Market Leadership & Expertise

- Quality Assurance:

- Stringent quality control processes ensure products meet the highest standards of durability, functionality, and safety.

- Regular audits and certifications maintain global compliance.

- Client Collaboration:

- Partners with clients to deliver tailored packaging solutions.

- Solutions enhance product appeal, extend shelf life, and improve sustainability, backed by innovative technology and reliable service.

- Quality Assurance:

Unmatched Prepress Capabilities at Hotpack Global

At Hotpack Global, we redefine industry standards with our exceptional prepress capabilities. Our fully integrated in-house system for plate making and die making sets us apart, ensuring unparalleled quality and efficiency. With cutting-edge technology and advanced processes, we lead the way in the packaging industry. Here’s an in-depth look at our prepress strengths:

-

Integrated In-House System

- Holistic Approach: Our end-to-end system handles every aspect of production internally, from design to final product. This integrated approach eliminates the need for external vendors, delivering faster turnaround times and superior quality control.

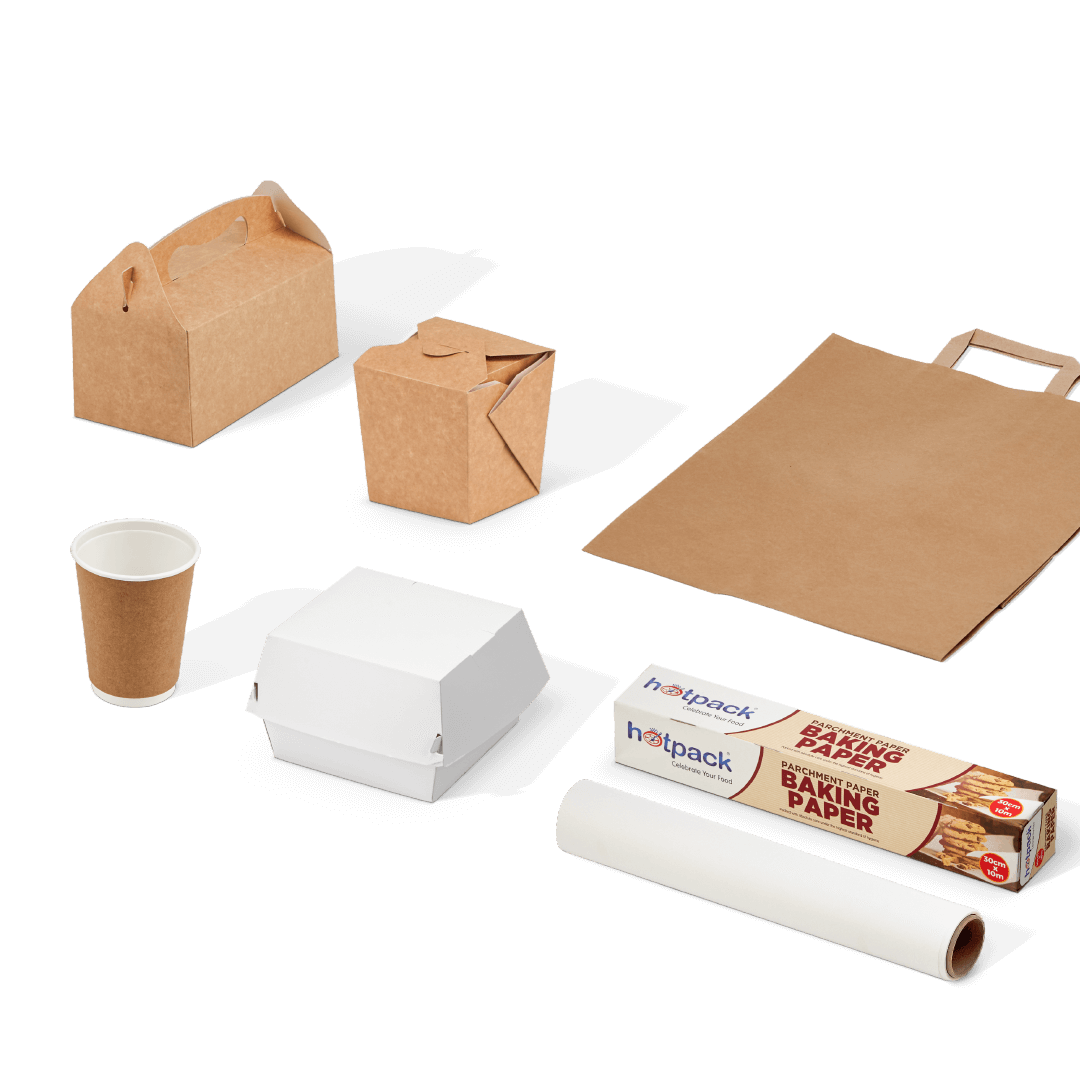

- Comprehensive Solutions: We cater to a broad range of needs, including folding cartons, labels, paper cups, LDPE shopping bags, and pouches, all managed under one roof.

-

Advanced Prepress Technology

- Esko XPS Crystal Technology:

- Energy Efficiency: The Esko XPS Crystal system offers up to 59% energy savings compared to traditional UV bank light frames. This significant reduction in energy consumption lowers operational costs and aligns with our commitment to environmental sustainability.

- Waste Reduction: Utilizing UV LEDs, the Esko XPS Crystal achieves a 92% reduction in waste of light elements over its lifetime. This technology is a major advancement from mercury-containing UV lamps, contributing to a greener production process.

- Enhanced Performance: The Esko XPS Crystal ensures precise plate exposure consistency, improving print quality and operational efficiency.

- Centralized Prepress Division:

- Flexo and Offset Plate Making: Our advanced division features the Esko XPS Exposing System, ensuring high-precision plate quality for flexo and offset printing.

- Kongsberg Sample Cutting Machine: This machine creates accurate prototypes and samples, allowing us to verify designs before full-scale production.

-

High-Precision Automation

- Minimized Manual Intervention: Extensive automation processes reduce human error and enhance efficiency, maintaining a near error-free environment.

- Advanced Plate Mounting System: Designed for the corrugation industry, this system ensures precise plate positioning and registration, resulting in exceptional print quality.

-

Cutting-Edge Software Solutions

- Automation Engine: This server-based workflow solution automates preflighting, trapping, color management, and file output, reducing manual intervention and ensuring consistent quality.

- ArtiosCAD: The world’s leading structural packaging design software, ArtiosCAD, allows us to create innovative and functional packaging designs with 3D visualization and material optimization.

- ArtPro+: This native PDF editor streamlines file preparation with efficient adjustments for trapping, color management, and layer handling, ensuring print-ready designs.

- Studio: Studio software provides realistic 3D mockups of packaging designs, allowing us to visualize and refine designs before production.

- Plato: Plato facilitates efficient step-and-repeat layout creation, optimizing sheet usage and ensuring precise alignment and registration during printing.

- Pack Proof: Pack Proof simulates color accuracy and consistency, ensuring brand colors are maintained and the final product meets client expectations.

-

In-House Die-Making Facility

- Advanced Die-Making Capabilities: Our facility produces flatbed dies and male and female stripping dies for various applications, including folding cartons and corrugated packaging. This in-house capability ensures precise control over die quality and production timing.

-

ESKO WebCenter Capabilities

- Streamlined Project Management: ESKO WebCenter provides a comprehensive platform for managing packaging projects from design through to production. This cloud-based solution facilitates real-time collaboration, ensuring that all stakeholders have access to up-to-date information and can contribute to project decisions.

- Workflow Automation: WebCenter’s workflow automation tools streamline the approval process, manage artwork revisions, and track project progress, reducing turnaround times and enhancing efficiency.

- Brand Consistency: The platform ensures that all packaging designs adhere to brand guidelines and specifications, maintaining consistency across different production runs and geographical locations.

- Collaborative Tools: WebCenter’s collaborative features allow for seamless communication between design teams, clients, and production staff, ensuring that feedback and approvals are managed effectively.

- Data-Driven Insights: The solution provides valuable analytics and reporting tools, offering insights into project performance and helping to identify areas for improvement.

-

Commitment to Sustainability

- Eco-Friendly Practices: Our investment in sustainable technologies, including the Esko XPS Crystal, helps us minimize our environmental impact. By reducing energy use and waste, we support our sustainability goals while delivering top-quality products.

Partner with Hotpack Global

Choose Hotpack Global for unparalleled prepress capabilities, advanced technology, and a commitment to sustainability. Our integrated approach ensures the highest standards in every project, from design to final product, making us your ideal partner in packaging solutions.