Q1: How Packaging Can Extend Food Shelf Life

A1: At the most basic level, packaging is used for the purpose of carrying or transporting a material from point A to point B. However, in its most complex role, it protects the food from outside contaminants and preserves its inherent goodness for much longer time than otherwise possible in the natural environment. This is called extension of shelf life of food through and is achieved by making specially constructed packaging made of two or more types of polymer substrates often in combination of an aluminium film. An appropriate shelf life ensures that quality food is available for consumers for a much longer time, helps a distribution network to carry food over long distances to all geographical corners without the risk of food spoilage, and also enables production efficiencies associated with larger product volumes. This means right packaging provides more time for transportation, more time for selling sensitive food products, and reducing spoilage making food products highly attractive to the customers.

Food generally becomes unfit for consumption by over exposure to oxygen or moisture or both which cause microbial growth leading to its deterioration. For example, if left in the open for long, biscuits become soggy – they lose their crunchiness and thus become less tasty as also the majority of snack foods which lose their crispness & aroma if left in the open for long. Coffee also turns into lumps if not kept in tight packs. There are thousands of such daily-use products whose consumption life is incredibly extended by specifically made packaging.

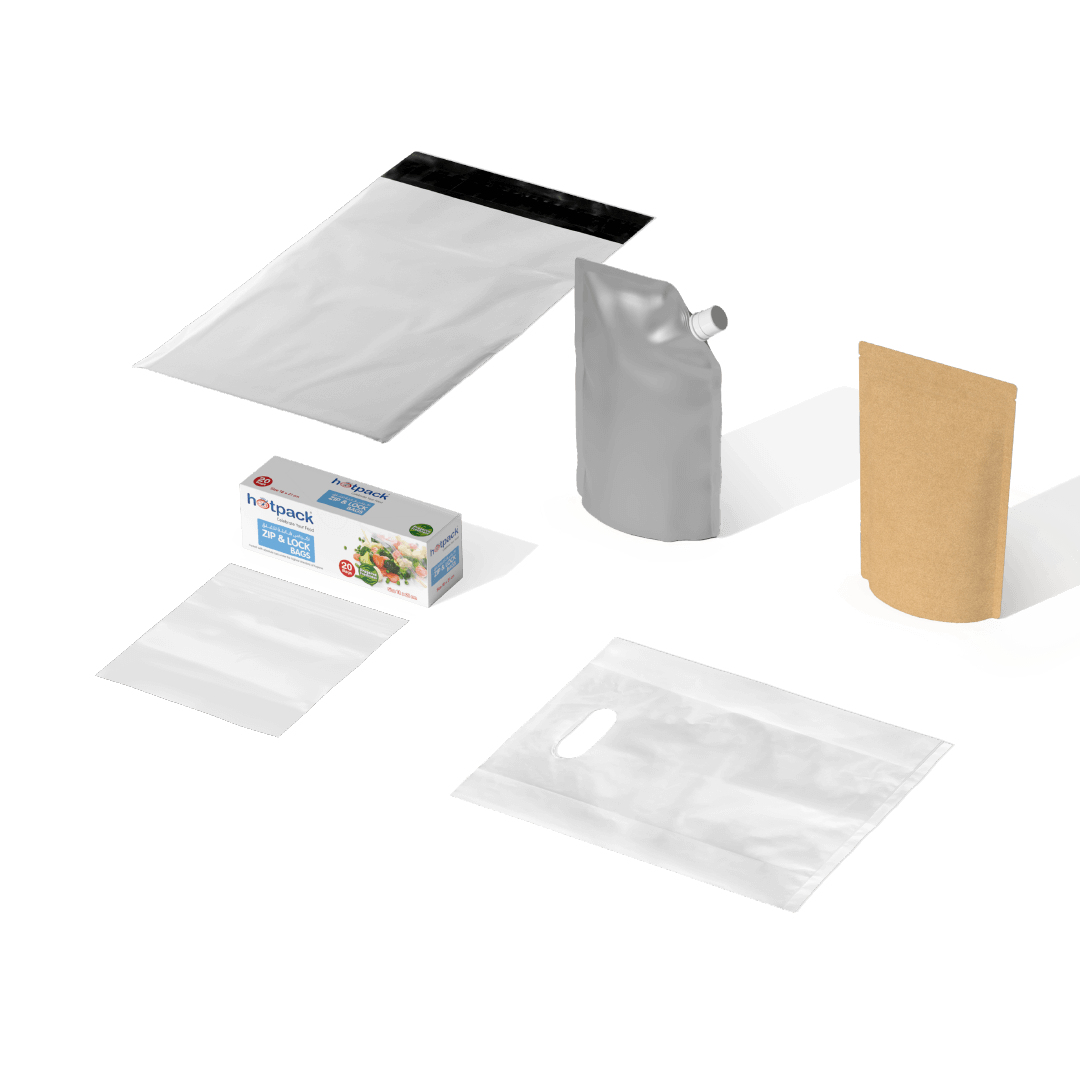

There are many different types of plastic polymers like Polyester, Nylon, Ethylene, propylene coupled with special material like foil which have barrier properties of varying degrees and are used for shelf life extension of food products during the industrial processes. This purpose-built packaging generally is a combination of two or more such polymers along with a foil (coating or film) fused together to make a seamless structure. This more complex packaging thus acts as a barrier between oxygen & moisture and the food contents ensuring longer life for the products to be available to consumers in the supermarkets.

Q2: What can we do to increase the shelf life of a food item

A2: There are conventional methods which are followed at every home like heating the food as per its suitability, drying certain types of food categories, ignoring the best-before dates in certain cases like Rice, sugar, honey etc, controlling fridge temperature, freezing just about everything, keeping food covered airtight etc. These are home practices and are followed at the customer-end to deal with small portions of food for a relatively shorter period of time. However, at the industrial level, more scientific and advanced methods are followed for food preservation in the context of packaging. As earlier discussed, there are many different types of plastic polymers like Polyester, Nylon, Ethylene, propylene coupled with special material like foil which have barrier properties of varying degrees and are used for shelf life extension of food products during the industrial processes. This purpose-built packaging generally is a combination of two or more such polymers along with a foil (coating or film) fused together to make a seamless structure. This more complex packaging thus acts as a barrier between oxygen & moisture and the food contents ensuring longer life for the products to be available to consumers in the supermarkets.

Q3: Which is the best type of plastic for food packaging?

A3: Depending upon the time required for the product to remain fit for consumption, different types of plastic polymers are chosen for their varying barrier properties.

The choice of packaging material for shelf-life is not at all about the best available, but about the most suitable for a particular period of expiry requirement.

For example, bread & bakery products are dated for a short period of consumption like 3-7 days, therefore, a common basic level mono-material like Polyethylene is used for almost all sliced breads & Asian bread types. Croissants, buns etc are usually packed in cPP or BoPP material to give a better level of barrier since these products usually carry a slightly longer like 7 days of expiry. Snack foods most commonly require a higher level of packaging because of their sensitivity to oxygen & moisture and their need for preservation of freshness. Snacks like biscuits, chocolates, chips, seeds, muffins, nuts, candies etc not only require a longer shelf-life of 6-12 months but they need their specific tates, aroma, texture, feel, state to be retained till their long expiry period. Therefore such products require multi-layer packaging which is a combination of two or more than two types of the same or different polymer materials to ensure their consumption integrity over time. Thus a general rule is that: longer the shelf-life required, more complex the packaging will be.