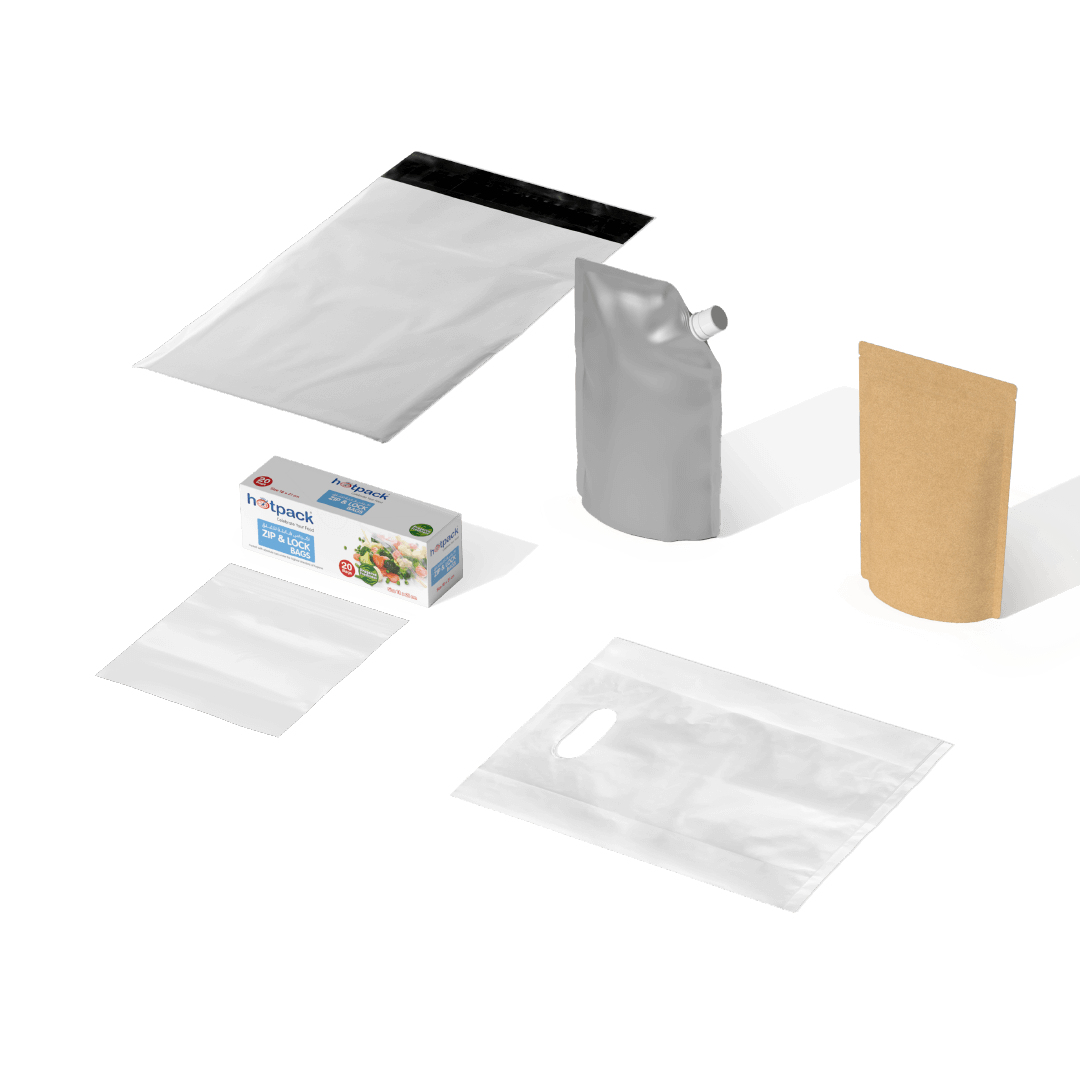

Depending upon the time required for the product to remain fit for consumption, different types of plastic polymers are chosen for their varying barrier properties.

The choice of packaging material for shelf-life is not at all about the best available, but about the most suitable for a particular period of expiry requirement.

For example, bread & bakery products are dated for a short period of consumption like 3-7 days, therefore, a common basic level mono-material like Polyethylene is used for almost all sliced breads & Asian bread types. Croissants, buns etc are usually packed in cPP or BoPP material to give a better level of barrier since these products usually carry a slightly longer like 7 days of expiry. Snack foods most commonly require a higher level of packaging because of their sensitivity to oxygen & moisture and their need for preservation of freshness. Snacks like biscuits, chocolates, chips, seeds, muffins, nuts, candies etc not only require a longer shelf-life of 6-12 months but they need their specific tates, aroma, texture, feel, state to be retained till their long expiry period. Therefore such products require multi-layer packaging which is a combination of two or more than two types of the same or different polymer materials to ensure their consumption integrity over time. Thus a general rule is that: longer the shelf-life required, more complex the packaging will be.