In today’s global landscape, sustainability isn’t just a buzzword; it’s a necessity. As consumers and businesses alike recognize the importance of responsible practices, the concept of a circular economy is gaining momentum. At Hotpack, we are committed to leading the charge towards a more sustainable future, and one of the ways we’re doing this is by embracing the circular economy in food packaging.

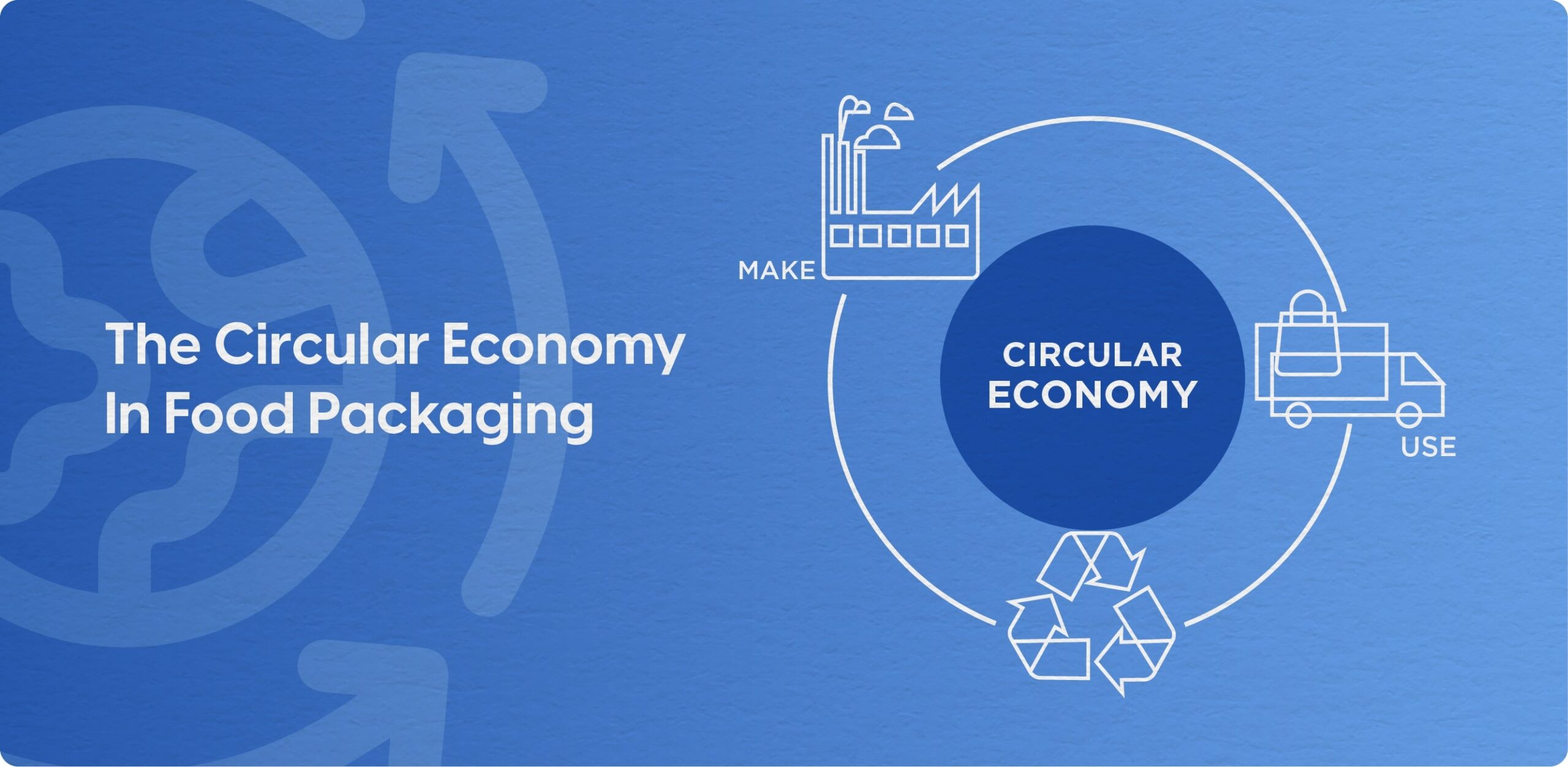

What is the Circular Economy?

The circular economy is an economic model that prioritizes sustainability, resource efficiency, and waste reduction. Unlike the traditional linear economy, which follows a “take, make, dispose” pattern, the circular economy aims to create a closed loop where products and materials are continually reused, refurbished, remanufactured, and recycled.

The Next Step – The Ultimate Circular Economy?

The ultimate circular economy envisions the ability to manufacture goods, such as food packaging, that facilitate the products to be used many times and then reprocessed/re-manufactured back into the same or very similar goods. This single closed loop is becoming possible in many of Hotpack products and our R&D teams are working with a variety of partners to explore this ‘Holy Grail’ of sustainable solutions.

Circular Economy Principles in Food Packaging

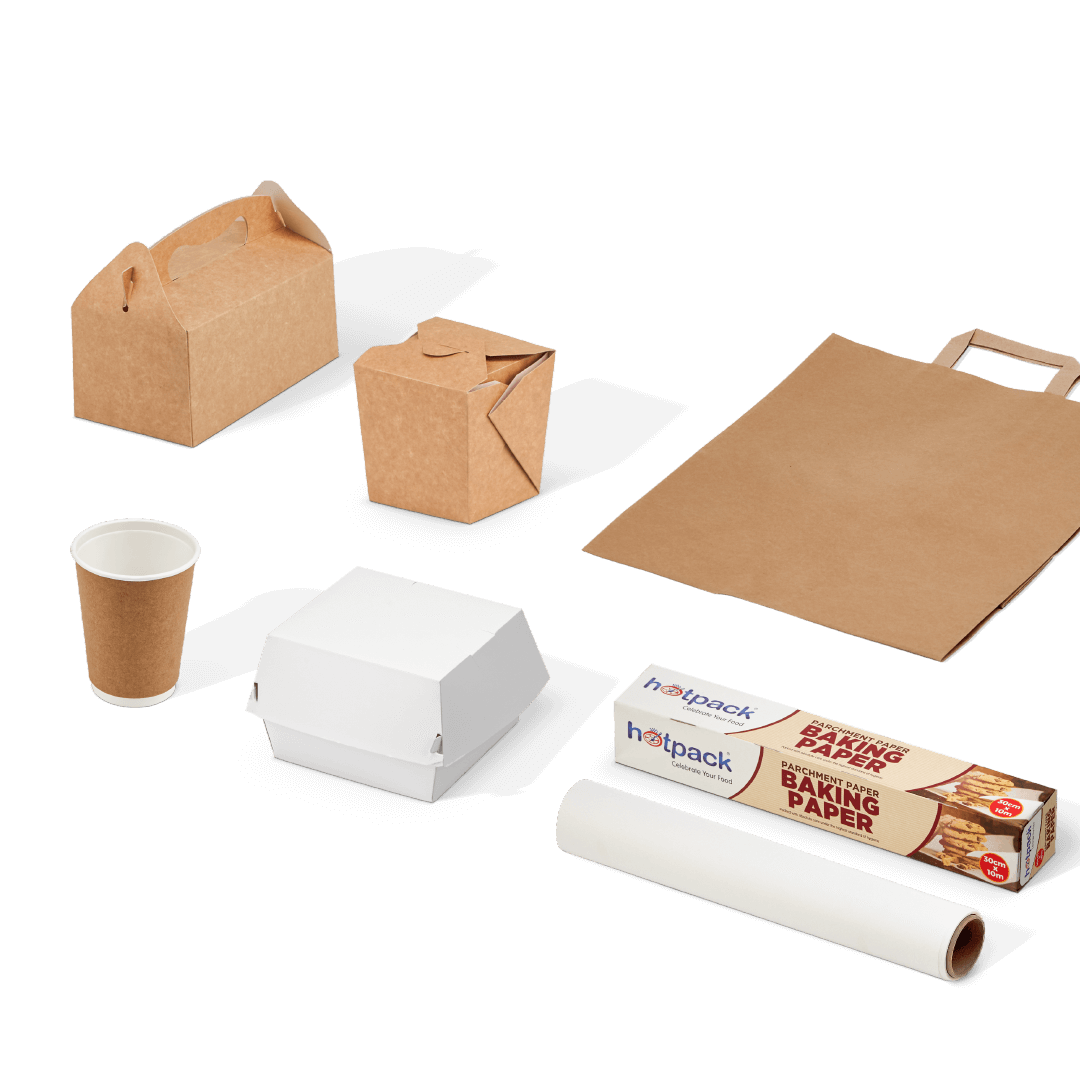

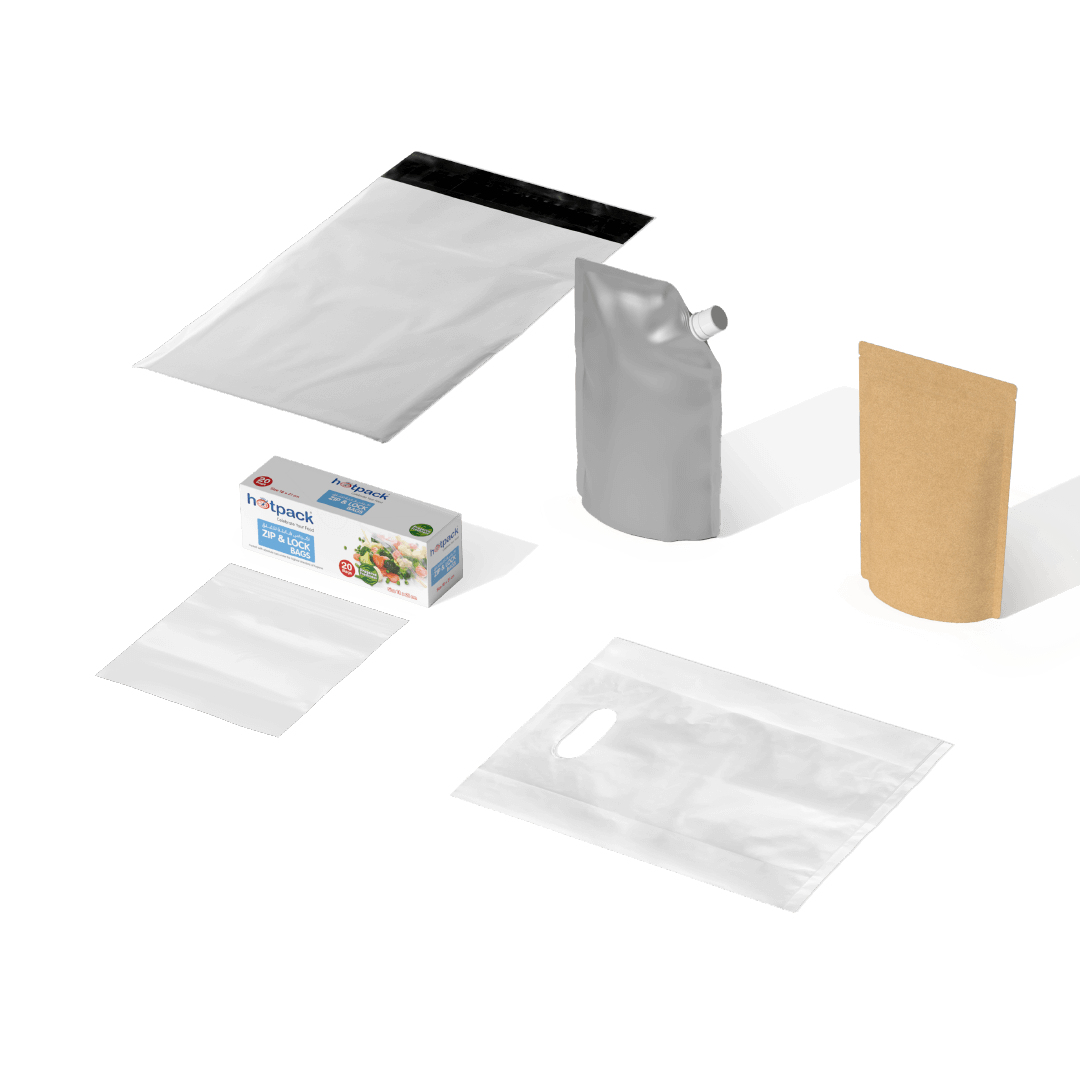

- Design for Longevity: In the circular economy, products are designed to last longer, reducing the need for frequent replacements. Hotpack’s food packaging is engineered for durability and performance, extending product life cycles.

- Reusable Packaging: Hotpack promotes reusable food packaging solutions that minimize single-use waste. Our reusable containers and utensils are designed to withstand multiple uses, reducing overall environmental impact.

- Recycling and Repurposing: Circular economy practices emphasize recycling and repurposing materials. Hotpack embraces recycled materials like rPET, rPP, and rPE in our food packaging products, reducing the demand for virgin plastics.

- Resource Efficiency: Efficiency is a core principle of the circular economy. Hotpack invests in resource-efficient manufacturing processes and collaborates with recycling partners to minimize waste and resource consumption.

- Waste Reduction: By implementing strategies like zero-waste manufacturing and designing packaging that generates less waste, Hotpack actively contributes to reducing waste in the food packaging industry.

Hotpack’s Commitment to the Circular Economy

At Hotpack, we take our role in advancing the circular economy seriously. Our commitment to this model is evident in the following ways:

- Sustainable Sourcing: We prioritize responsible sourcing of materials, including recycled plastics, to reduce our environmental footprint.

- Product Innovation: Hotpack continually innovates to develop food packaging solutions that align with circular economy principles, such as reusable and recyclable options.

- Waste Reduction: We are dedicated to minimizing waste in our operations and encourage our customers to do the same by choosing sustainable packaging solutions.

- Education and Awareness: We believe that educating our stakeholders about the benefits of the circular economy is essential. We actively engage in awareness campaigns to promote sustainable practices within our industry and beyond.

Closing Thoughts

The circular economy is not just a trend; it’s a transformative approach that holds the key to a more sustainable future. By adopting circular economy principles in food packaging, businesses can reduce their environmental impact, enhance their brand reputation, and meet the growing consumer demand for eco-friendly products.

At Hotpack, we are proud to be pioneers in embracing the circular economy in food packaging. Together with our partners and customers, we are working towards a world where packaging doesn’t just protect our food; it protects our planet too. We have a number of projects aimed at achieving the ultimate circular economy. It is now technically possible to make PET drinking cups, collect them after use and then clean & re-process them back into the same rPET drinking cups. Key to the success of these innovative solutions will be the education of the public to help sort and clean these products at home/work so that they can most recirculated with minimal waste and contamination.

Join us at Hotpack in closing the loop and making a positive impact on the environment, one sustainable food package at a time. Choose Hotpack for packaging solutions that reflect our shared commitment to a circular and sustainable future.