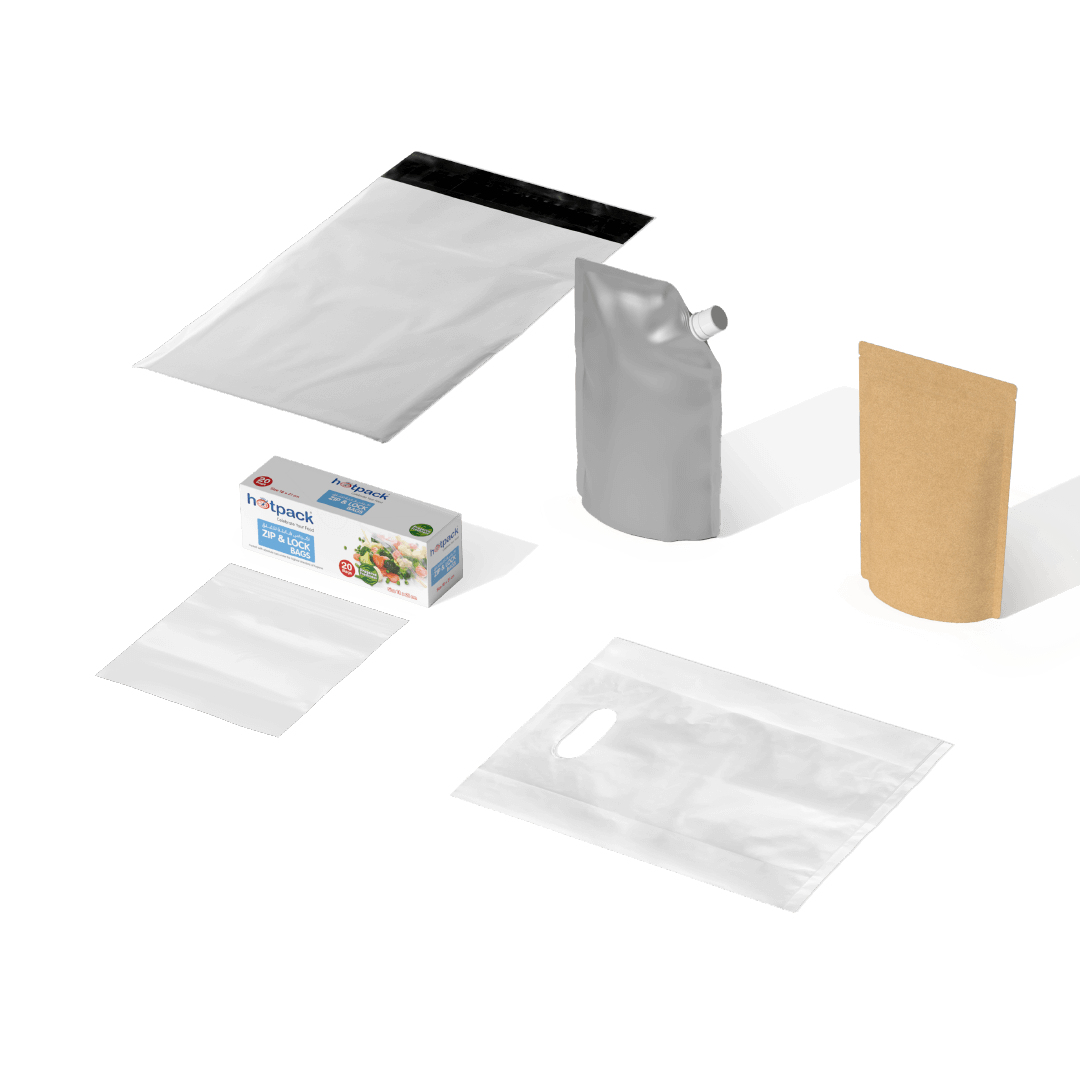

Flexible packaging has become the go-to solution for packaging a variety of products . Thes products could be food items or consumer goods. Be it bags, pouches, wraps or other forms of flexible packages; they offer several advantages over rigid containers. They conform to any product shape or size, are lightweight and affordable. Flexible packaging also helps extend product shelf life while reducing environmental impact. With growing demand for convenience and sustainability, flexible packaging solutions are gaining popularity. This article explores top 5 reasons why more companies should consider flexible solutions for their packaging needs.

-

Convenience and Flexibility

Flexible packaging offers unparalleled convenience and flexibility when it comes to packaging products. The flexible pouches, bags and wraps can be easily bent, folded or twisted to perfectly fit any product shape or size. This makes them highly adaptable packaging solutions.

Whether the products are irregularly shaped fruits and vegetables or uniquely designed consumer goods, flexible packaging can form-fit to the contours of the item. They mould themselves around the product, reducing empty voids and empty spaces. This allows for efficient utilisation of packaging film or material.

The lightweight and pliable nature of flexible packages also makes them extremely portable and convenient to store or transport. Products sealed in pouches or bags take up very little space and are easy to stack or carry. This makes flexible packaging an ideal option for on-the-go consumption. Flexible packages are not restricted by the size and shape of products. Unusual or oddly shaped items that do not fit standard rigid containers can be effortlessly packaged in pouches or wraps. Last minute adjustments to packaging dimensions are also possible which is difficult with rigid alternatives.

-

Durability

Flexible packaging materials are designed to be durable and withstand the rigors of transportation and storage. Being lightweight, flexible packages have to face frequent bumps, drops and pressure during their journey from manufacturer to retailer to consumer. Subjected to these stresses, rigid containers are prone to cracking or damage. However, flexible packaging can take the abuse and protect products inside.

The materials used for flexible pouches, bags and wraps are tough and resilient in nature. Many flexible films are multilayer laminates combining polymers like polyethylene, polypropylene, polyester etc. The layering and blending of materials provides strength without making the packaging stiff. It allows flexible packages to absorb impact through controlled flexing and bending instead of breaking.

During transportation, flexible packages are compressed and stacked with other shipments. The packaging has to withstand tremendous pressure without crushing. Tough flexible films maintain their shape to a great extent in such conditions. Any dents or impressions returned back once pressure is released, unlike rigid containers that may crack under strain.

-

Freshness

One of the key advantages of flexible packaging from reputed flexible packaging suppliers is that it helps keep products fresh for longer durations. Flexible packages provide an effective barrier against various elements like moisture, oxygen, dust, microbes and other external contaminants that can lead to spoilage of products.

The packaging film or laminate used for flexible pouches, bags, wraps etc. are specially designed to prevent or drastically reduce transmission of gases and moisture. Metallic foils, polymer coatings and advanced laminate layering in the film create highly effective moisture and gas barriers. This protects products from external environmental factors.

Inside the package, flexible films also control the internal environment. They maintain optimal moisture and gas levels surrounding products to slow down natural deterioration processes. The adjustable and tight seals of flexible packages do not allow air or moisture exchange, locking in freshness. Re-sealable features in pouches and bags with zippers or adhesive strips allow consumers to access the contents while maintaining the protective barrier. Upon resealing, they again cut off contact from external conditions, extending the shelf life compared to rigid containers with single use lids.

-

Sustainability

Flexible packaging is more environmentally friendly compared to rigid containers in several ways. During production, flexible packages require less raw material as they can be manufactured in thin gauge films compared to bottles, cans and boxes. This reduces the amount of material used and saves natural resources.

Being lightweight also means flexible packaging has a lower carbon footprint during transportation. Less fuel is consumed to transport the same quantity of goods packaged in flexible films rather than heavy rigid alternatives. This significantly reduces greenhouse gas emissions released into the atmosphere.

As the packaging moulds itself tightly around the product, there are no excess or empty spaces inside. This optimizes the use of packaging material. Rigid containers on the other hand have a fixed shape and often a lot of empty headspace is left inside when not completely filled. Additionally, most flexible films are recyclable or even compostable. Many flexible packages already in the market are made from recyclable polyethylene and polypropylene resins. Some newer types are completely home compostable.

-

Cost Effectiveness

Flexible packaging solutions tend to be more cost effective than rigid packaging formats like boxes, bottles or cans due to several key factors. Flexible films, pouches and bags require less raw material to produce since they can be molded to any shape, minimizing excess material waste and saving substantially on production costs compared to rigid containers made of materials like plastic, glass or metal.

Being lightweight, flexible packages also consume less fuel and take up less shipping space. This allows manufacturers to transport more products using the same vehicles and shipping containers than if rigid packages were used. The reduced distribution and freight costs associated with flexible packaging provide significant savings.

Flexible packaging films are also tailored closely to the shape and size of products without empty spaces. This maximizes the utilization of packaging surface area. Rigid containers on the other hand generally have fixed dimensions, resulting in unused headspace that wastes material. Flexible packages therefore use packaging materials far more efficiently. The cost savings from lower production outlays, more efficient material usage and reduced distribution expenses allow flexible packaging budgets to stretch much further.

Conclusion

The food packing container scores high on convenience, protection, sustainability and cost factors making them a good choice for various industries and applications. Their advantages outweigh traditional rigid packages for many products.

To read The Evolution and Significance of Flexible Packaging Manufacturers and Suppliers – Click Here